Amidst rapid development in technology, unmanned aerial vehicles (UAVs) are becoming increasingly popular in various domains since they’re far more superior than their manned counterparts. Power line inspection is one domain where UAVs or drones offer massive potential with enhanced speed, efficiency, safety, and data management systems.

The Hepta Aircraft

The EU has over eleven million kilometres of power lines. Currently, 90% of critical infrastructure inspections are done on foot, which is highly ineffective in many ways; it’s expensive and prone to errors. A manned aircraft carries the risk of crashing into power lines and causing severe injury or death to the pilot, hence why it’s a dying field. These risks can be completely avoided with UAVs.

In a recent case in Estonia, two manned crews struggled in a residential area for two years and couldn’t find what was causing around a hundred homes to be left in the dark. When the municipality finally turned to us, our drone crew detected 137 defects on one line with 53 poles in one day.

Hepta UAV inspection makes it possible to quickly and safely access areas that may pose health, safety, and environmental risks. The Hepta drone can easily hover between masts and focus on small elements that need surveillance.

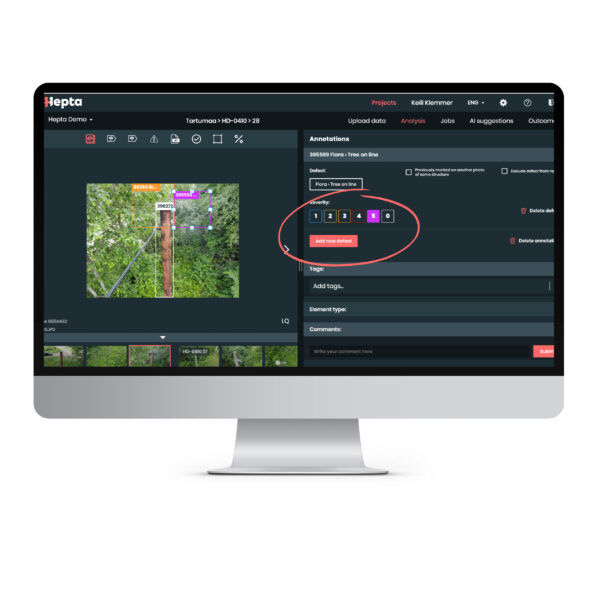

We have developed the first autonomous end-to-end power line inspection technology. Our aircraft can withstand harsh weather conditions, and the AI-driven software is ready to detect potential problems. It consists of an in-house–developed UAV, upgraded sensors, and an autonomous post-flight data analysis platform. Our technology can automatically inspect hundreds of kilometres of power lines and analyse the collected data.

What a Typical Drone Survey Pilot Project Looks Like

When our clients ask us what they need to begin a pilot project, the number-one priority is the list of power line locations. Upon flying a manned aircraft, the pilot can see where the line is and direct the helicopter manually. With unmanned aerial missions, the flight data is pre-programmed, and for that, we need very accurate line location data.

In the next phase, we perform an initial analysis of the terrain and the area of interest; based on that, we can move forward. Then we need the customer’s “wish list”. We provide a checkbox solution where the customer can select precisely what they need. During a phone call or email correspondence, we gather all the information and align our goals. Based on this, we can calculate the price.

Typically, a transmission or distribution company understands what kind of quality LiDAR point clouds they want to have and the absolute and relative accuracy of a point cloud and the image as well as per-pixel and per-centimetre accuracy. So we can provide an estimate – a benchmark to meet those standards or, better yet, exceed them.

Typically, the pilot project flight is between 30 and 50 kilometres, which is more than enough to test out all of the service’s capabilities and possibilities. During the flight, we examine power lines of various voltage levels so that the customer can be informed on how low-, mid-, and high-voltage power line data are processed.

Additional Know-How

- The best time to perform the UAV inspection is when there’s sufficient light for inspections; the preferable season is April–October, but it varies from region to region.

- Flight permits have two options: the client can either order the license acquisition as a service from a third-party company or leave it up to us (we strongly recommend this option). In addition to our experience obtaining beyond visual line of sight (BVLOS) flight permits in Portugal, Germany, Finland, Sweden, and Montenegro, some of our employees have commercial helicopter pilot licenses, which is why we know exactly how to communicate with the aviation authorities.

- The timeframe depends on the location; regions that are familiar to us take less preparation time. Areas with BVLOS flights naturally take longer and require extra steps.

Benefits of the Drone Inspection Pilot

The pilot project provides you with invaluable experience of the whole process – flight permit acquisition, data collection and processing, implementing machine learning to instantly detect the most common defects, and final reporting. Observe the kind of defects in what time frame and cost can be obtained and feel the potential of the latest technology that lets you save both time and money. Changing the approach of network inspections is difficult, but a good pilot project provides great experience and helps draw attention to areas that could be upgraded.

To sum up, these are the key benefits of the UAVs pilot project:

- Assessment of difficult-to-access areas

- Access to areas that pose health, safety, and environmental risks

- Authorized and qualified UAV inspection staff

- Automation

- Cost-effectiveness

- Fast response and reliability

- Comprehensive service

- Carbon-neutral approach to data collection