Unmanned aviation enables groundbreaking services that are not possible with more traditional technologies. While these services have massive potential, they also introduce significant safety risks and are tightly regulated to reduce the impact on society and property.

Flight safety is a non-negotiable priority for industrial drones

As a company pioneering more benign services of the unmanned aerial inspection of power lines, Hepta ensures that airborne security and safety are taken very seriously. In essence, this is one non-negotiable factor for us to be successful and gain the continued trust of our customers and airspace regulators. Regulatory approval is necessary to obtain “beyond visual line of sight” (BVLOS) flight permits essential for the productive inspection of long power lines.

Hepta team in Germany

Safety, by definition, requires Hepta’s team to rely on very specific and strict training, processes, and procedures.

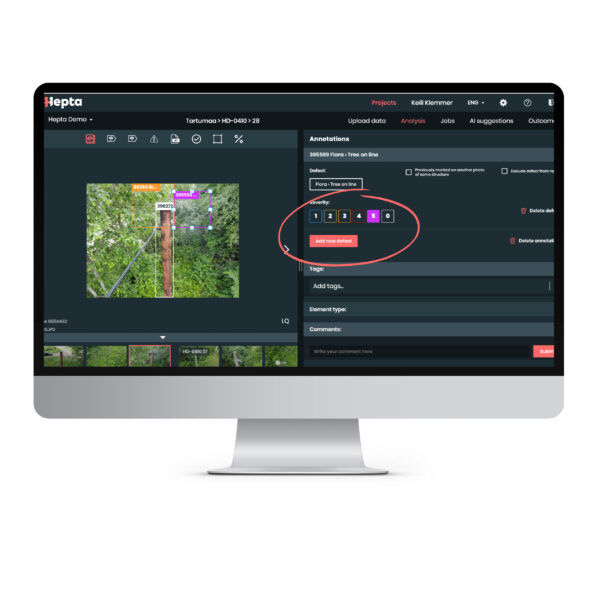

However, the same precision and meticulous attention to detail also enable Hepta to provide a high-performance service, get high-quality data, and execute flight missions at higher productivity, which also means better customer costs.

This approach also enables Hepta to react quickly when fast reaction time is necessary, such as doing a quick damage assessment after a storm. As a result, we at Hepta efficiently locate the disruptions, and the clients can direct technician teams to exact locations instead of checking the whole line to locate the breakage.

Hepta believes that highly standardised processes and procedures also help with future developments in the company’s services. This is because mature and optimised processes are easier to automate, thus further increasing productivity without an adverse impact on quality, and allows the company to get closer to the future of fully automated power line inspection services.

Drones must be engineered with safety in mind

The most apparent safety risk of unmanned aircraft operations is the aircraft itself. Just like everything heavier than air, there is a risk of unscheduled landing or, in other words, crashes.

Increasing reliability is paired with the technological maturity of the aircraft and its design choices. Using an internal combustion engine (ICE) to power the unmanned helicopters carries a minimal risk of failure. However, it nevertheless exists.

To mitigate this risk, it is not uncommon to use two helicopter engines on manned aircraft. Hepta’s way is to equip unmanned helicopters with an electrical second engine. As a result, the aircraft can perform a controlled landing even in the unlikely case of the main engine’s failure.

There are no shortcuts to thousands of flight hours

There are no shortcuts in achieving the highest reliability of an aircraft. It took over one hundred years for manned aviation to achieve the level of safety we all enjoy today, and sadly, even then, accidents happen.

Similarly, for unmanned aircraft manufacturers, there is no way around the necessity for many thousands of flight hours and extremely disciplined engineering, maintenance, and flight operation processes. This approach allows the company to reach a level of technological maturity that is fit for safe BVLOS flight operations.

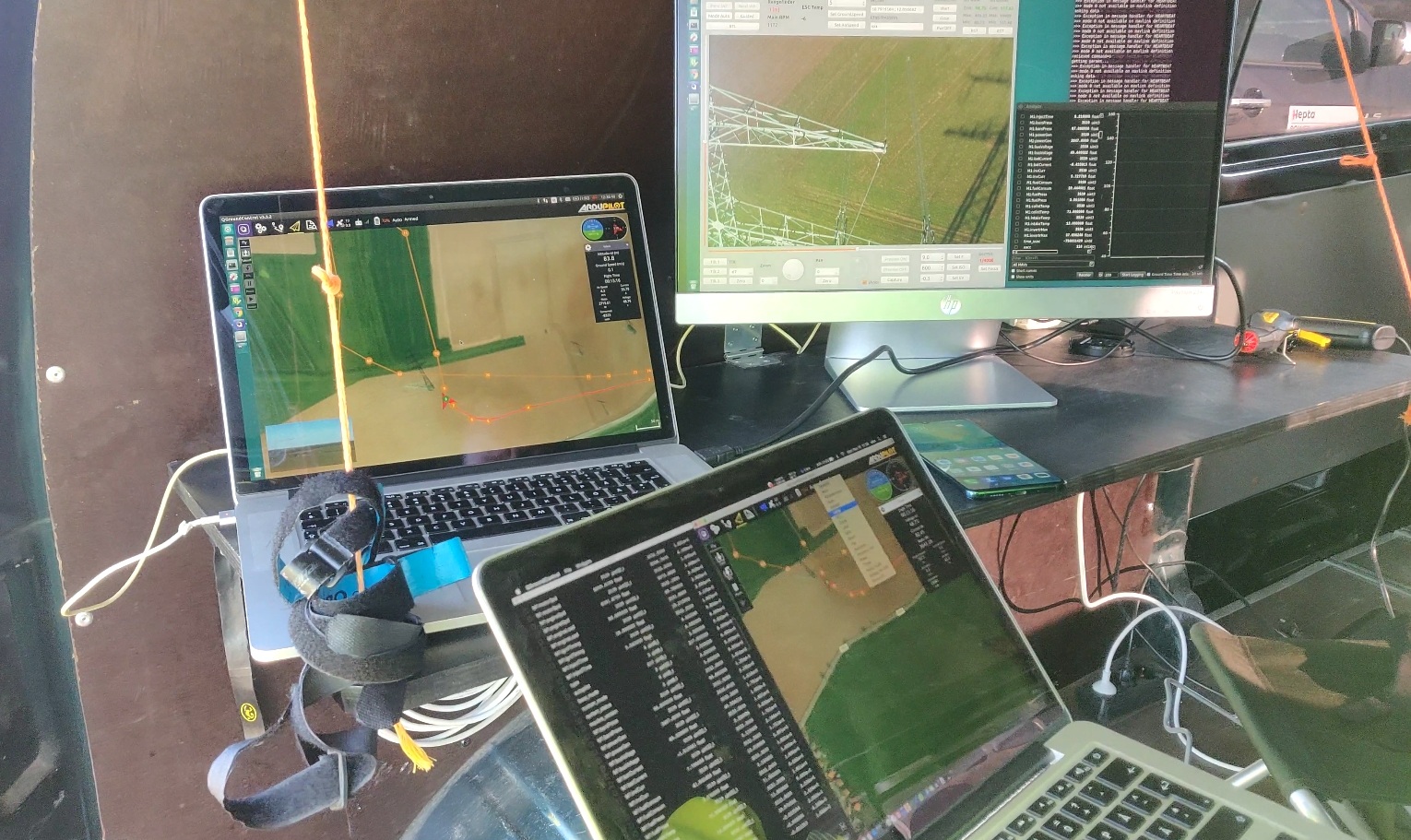

Hepta ground station for power line inspection drone BVLOS missions

People, processes, and procedures

While in the previous part, the focus was on aircraft technological maturity, it must be stressed that the reliability of aircraft critically depends on having properly trained people, processes, and procedures in place. This relates to planning the flight missions, operating the aircraft, ensuring proper maintenance, keeping records, and training and certifying the team.

Many Hepta team members have backgrounds in manned aviation. Three of them have manned helicopter pilot licenses, and many have been certified as manned aircraft maintenance technicians. Aviation is part of the company’s culture, and this allows Hepta to tightly embed the best practices and procedures of manned aviation into the safety and engineering aspects of its work.

Hepta team in Germany

A valuable side effect of this is the ease of engaging airspace regulators. Hepta speaks its language right from the start and is well-positioned to demonstrate their aircraft and flight operations’ safety and maturity. To this day, Hepta has successfully received BVLOS flight permits in every European country where it has applied for it.

At Hepta, every flight operator goes through extensive training. Such training covers safety procedures and flight operations and ensures that the aircraft is operated in the most productive way to collect high-quality data using a range of different sensors, each suited for a specific job.

Experience has shown that even aircraft operators with previous power line inspection experience can increase their productivity four times after attending training.

Conclusion

Flight safety is the most critical aspect that power line operators need to consider when exploring the possibilities of unmanned aircraft–based power line inspections. The service must be based on years of experience and thousands of logged flight hours backed up by well-documented safety procedures and thorough training. The aircraft model used to perform services should have thousands of flight hours and must have demonstrable safety features.

A good indicator of service maturity is the company’s previous track record and previous ability to obtain BVLOS flight permits from airspace regulators.

When you are interested in discussing our experience further or talking about a pilot project, please schedule a call with our VP of Engineering, Toomas Välja.