The most used power line defect detection method worldwide is RGB photography, but LiDAR power line inspection offers unique advantages. While universal in their usage, RGB photos have limitations on the amount of information that can be extracted from them and are used to detect current defects. LiDAR power line inspection, on the other hand, enables grid operators to create 3D models, which help to predict and detect future defects. The following article gives an overview of how LiDAR power line inspection works and where it offers the greatest advantages.

How LiDAR power line inspection works

LiDAR (short for Light Detection and Ranging) uses light in the form of a pulsed laser to measure ranges (variable distances) to the Earth. LiDAR targets an area with a laser and measures the time for the reflected light to return to the receiver. The light pulses help to generate precise, three-dimensional information about the shape of the inspected area and its surface characteristics.

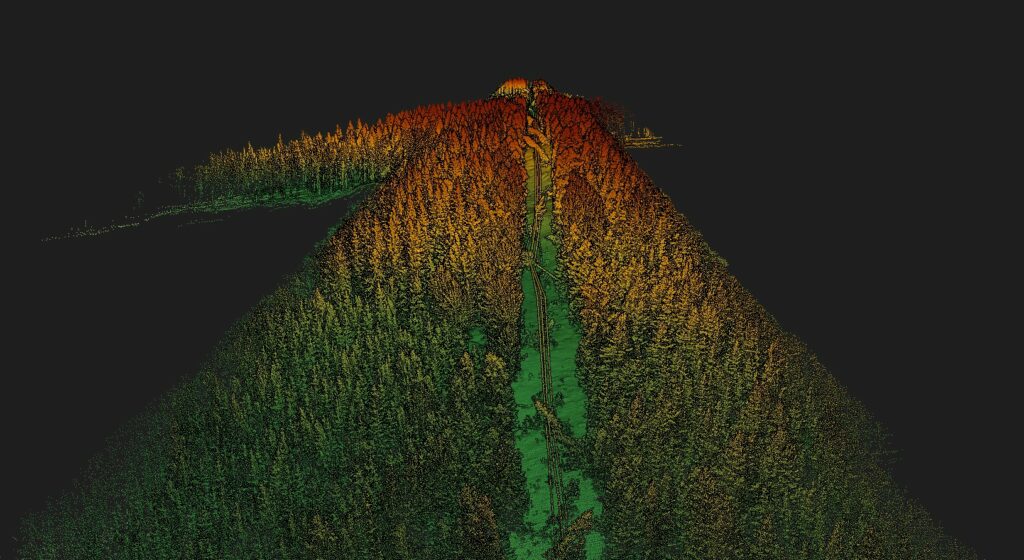

In power line inspections LiDAR is usually attached to a drone which then covers and measures the inspection area with multiple flights, allowing the creation of high-density point clouds. The higher the amount of measured points gathered by LiDAR power line inspection, the more information it is possible to get out of the 3D model created in the end.

Example of a 3D point cloud based on LiDAR measurements

LiDAR technology has a couple of drawbacks that one should consider when planning operations. One of them is that LiDAR needs relatively calm weather without precipitation to be used. Otherwise, there is a risk that the LiDAR readings will be affected by the weather and thus generate faulty point maps.

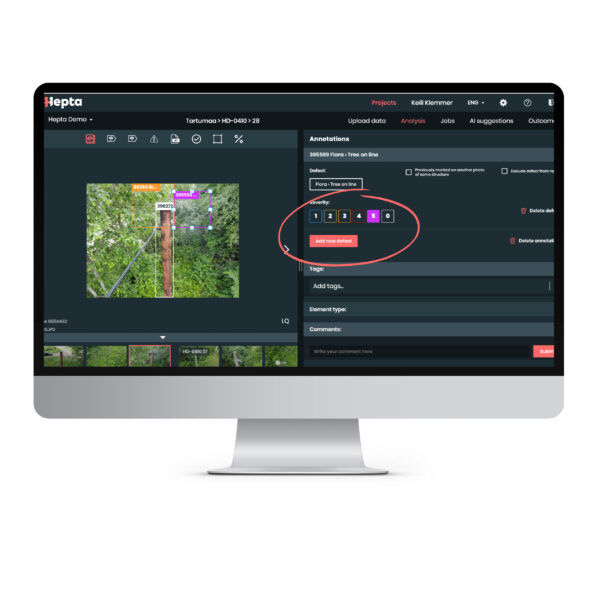

The data collected during the LiDAR transmission line inspection is usually uploaded to Hepta’s specialised power line inspection platform, Insights. This platform allows inspectors to analyse the data easily and detect defects. Hepta Insights also allows users to precisely measure distances between two points, allowing them to quickly understand the different objects surrounding their power lines and the threat they might pose.

LiDAR power line inspection advantages

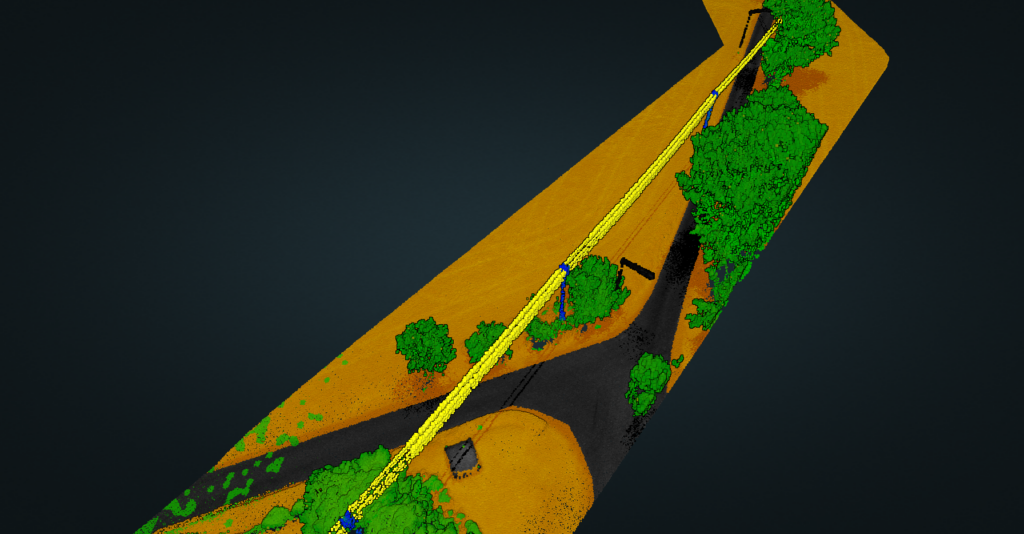

LiDAR use in power line inspection offers unique advantages. LiDAR point clouds and 3D maps allow grid operators to measure the distance between foliage, different vegetation, and power lines. This, in turn, allows them to make well-informed decisions and predict the areas that will become problematic in the near future. Instead of doing large-scale clearing operations, the grid operators can focus on the areas that pose the largest threat to the stability of their power line network.

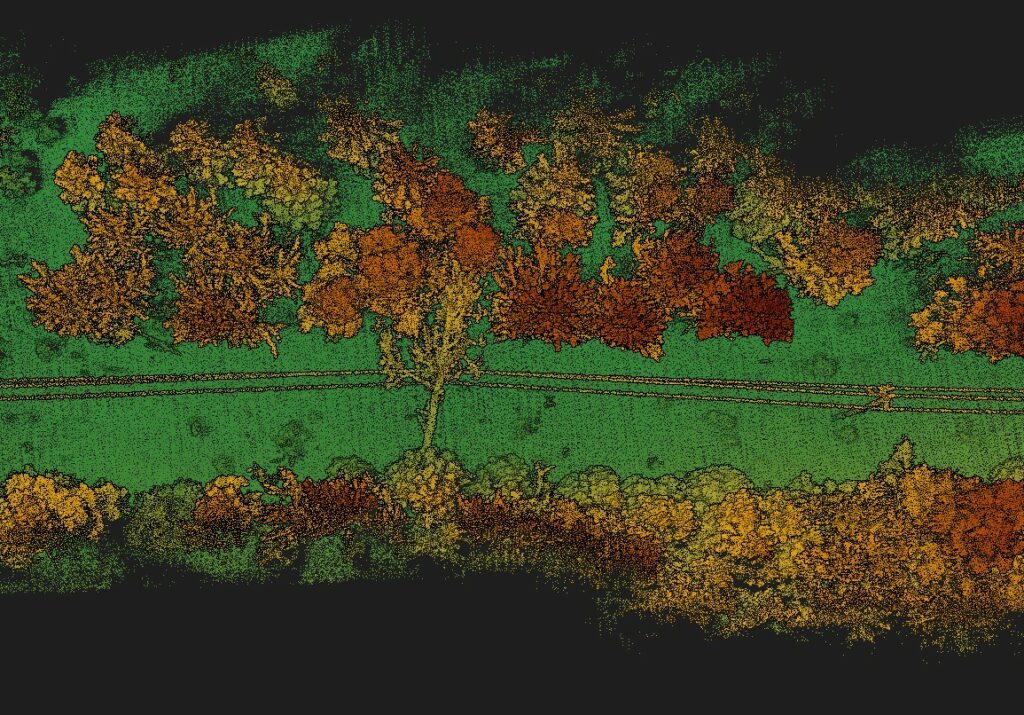

Vegetation close to power lines

LiDAR power line inspections also allow measuring wire profiles, enabling the grid operators to fix sagging power lines. LiDAR power line mapping is especially important in areas with high traffic density or large-scale machinery movement. For example, sagging power lines often threaten tractors and other farm equipment used in farming areas. Again, LiDAR power line mapping allows the grid operators to act before any damage is caused to the power line or machines working around it.

In post-storm observations, LiDAR power line inspections allow to detect tilting trees that are dangerously close to the power lines or might pose a threat, should they fall down. This again helps grid operators to make pre-emptive decisions and take action before storm-damaged trees might fall and cause blackouts. LiDAR power line inspections enable the grid operators to save time, money, and loss of revenue due to blackouts when taking the right actions based on good information.

One of the biggest advantages of LiDAR inspections is the speed of operations. LiDAR gathers measurements in split seconds, thus allowing for quick mapping of the area. Instead of days, weeks, or even months, huge swaths of land can be covered in hours. Considering the huge data-gathering prowess, LiDAR is also one of the cheapest transmission line inspection methods on the market.

A fallen tree on a power line

LiDAR power line inspection allows:

- Vegetation analysis

- Distance calculations

- Wire profiles and sagging detection

- Detection of dangerous trees

Hepta and LiDAR inspections

Hepta Insights has conducted hundreds of LiDAR power line inspections all over Europe. Its power line inspection platform, Insights, is used for defect detection and analysis on four continents and by a multitude of network operators. If you are interested in applying LiDAR inspections to your grid or have any questions regarding the capabilities of LiDAR-based solutions, feel free to contact Hepta’s experts and get answers to all your questions.