Detecting woodpecker damage on fibre-optic cables with drones – Connecto project

Hepta conducted a drone inspection project for Connecto to assess the extent of woodpecker damage on fibre-optic cables. Detecting woodpecker damage on poles during regular powerline inspections is a routine task, but this was the first time Hepta conducted an inspection to find defects caused by woodpeckers in the fibre-optic grid.

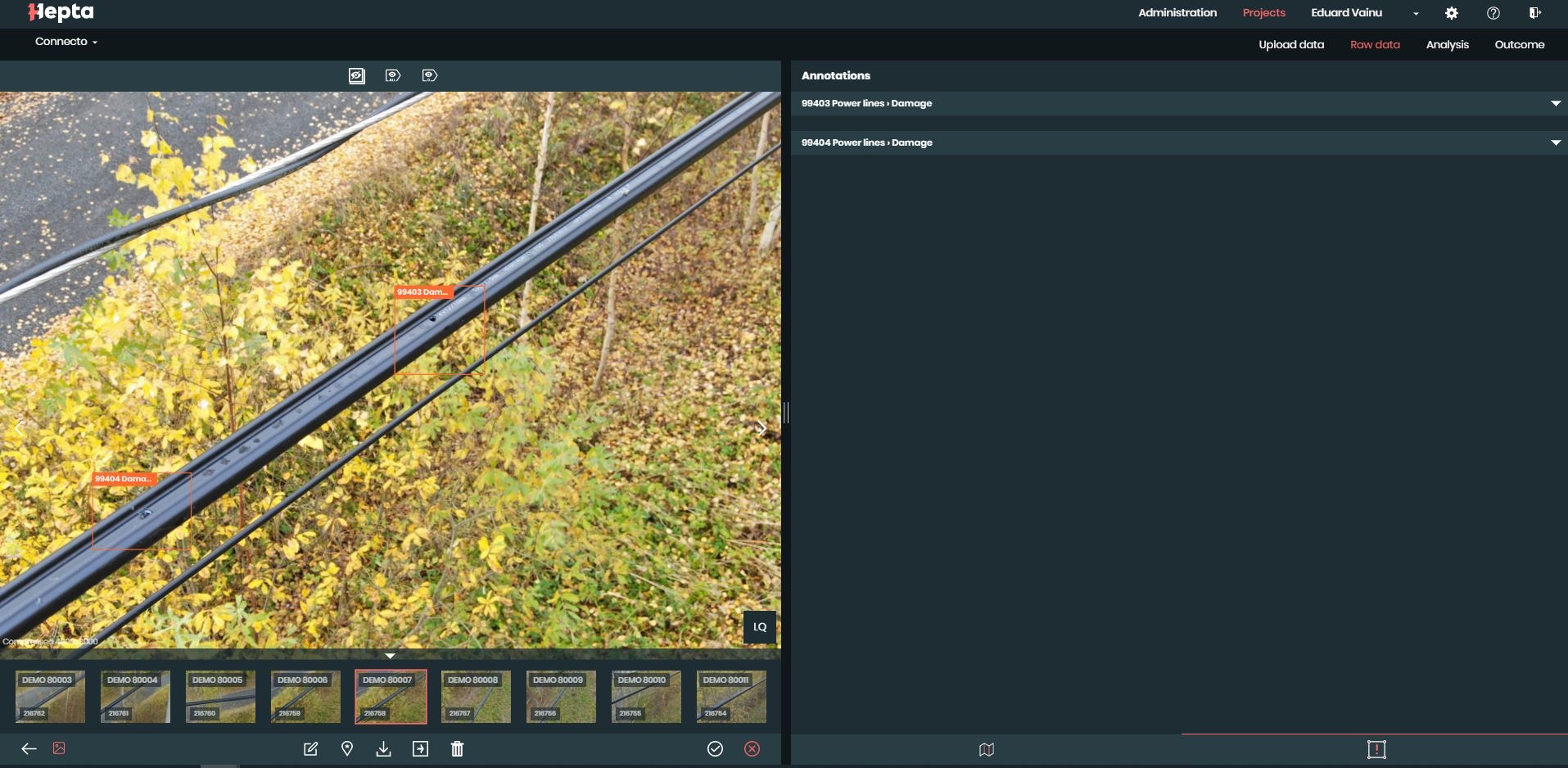

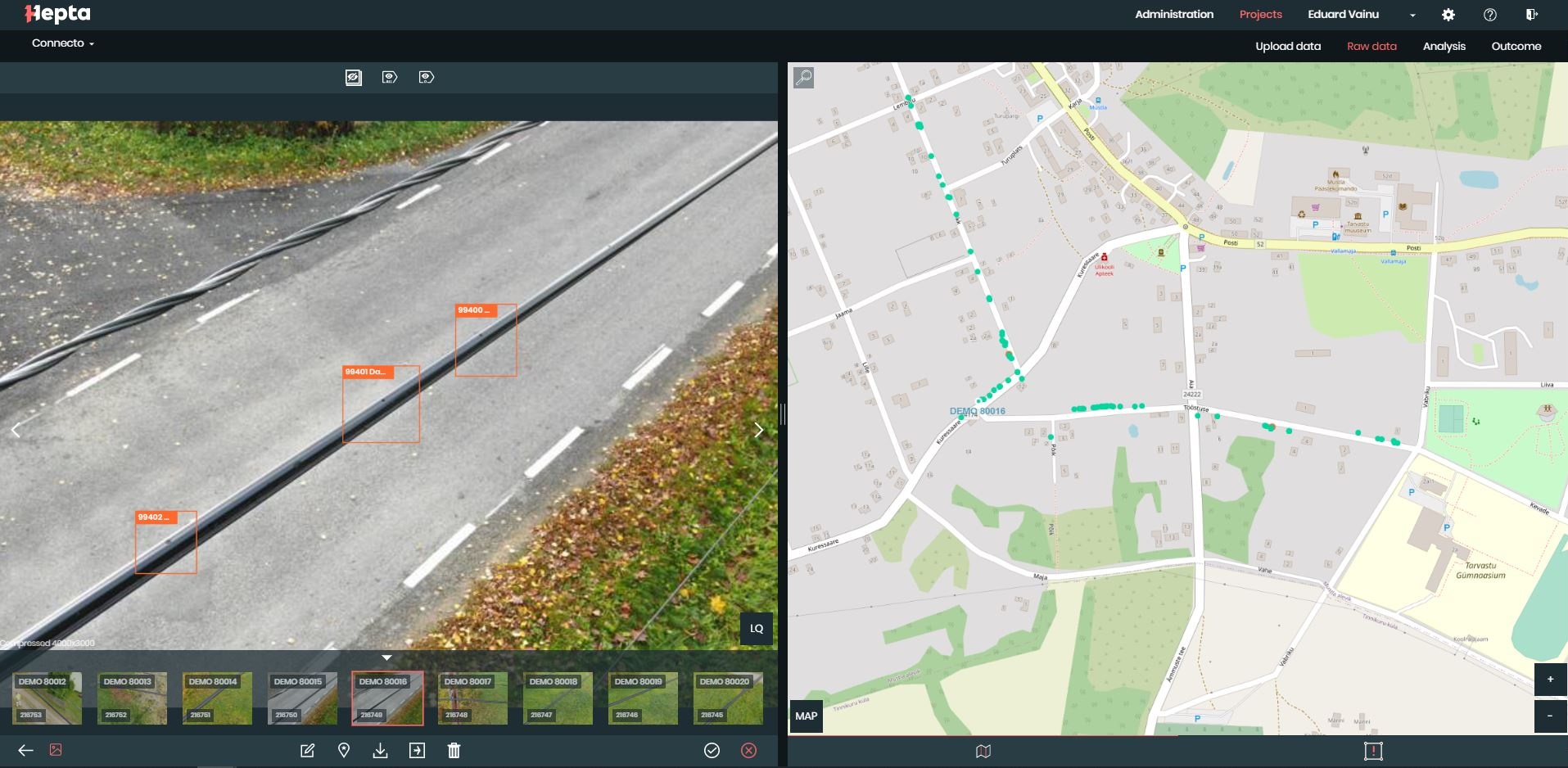

Example of woodpecker damage on fibre-optic cables in Estonia, defects marked in Hepta Insights Software.

Connecto specialises in designing, constructing, and maintaining electricity and telecommunications networks. Their main concern was the frequent internet interruptions experienced by clients in the Mustla area. Mustla is a small village in Estonia, one of the first to use ELASA high-speed internet. The cable is a transmission cable used by all telecommunication companies in Estonia, such as Telia.

Upon observation, it was evident that woodpeckers were attracted to the hollow fibre-optic cable shell and pecked eager holes into it in search of food. This problem has been recorded globally in woodpecker habitats.

In 2020, Connecto aimed to find all the damage and fix the defects causing connectivity issues. In this case, the cable is installed on the same towers as low-voltage and other communication cables. Assessing the foot would have required hiring an aerial work platform with a truck and two operators. It would also have been time-consuming, requiring lifting the team up and down, then moving forward and repeating the process multiple times at every single line section between the posts while marking down the defects.

As Hepta is already conducting a powerline inspection project for Elektrilevi and has a team all over Estonia, Connecto was curious if a similar technique could be applied to an inspection of fibre-optic cables.

The Hepta team was up for the challenge; The first job was to inspect a one-kilometre test section of line and display the results in Hepta Insights. After that, the Connecto team discussed the exact defects to search for and the most cost-efficient and speedy options to gather data. It was essential to agree on the defects and angles to capture. This kind of inspection takes a skilled drone pilot as most of the flying was done at a low altitude of four to five metres, under the lines, and very near vegetation.

The decision was to mark defects when at least one hole was in the cable section between two posts, annotate it in Hepta Insights, and allow the Connecto maintenance team to view it in Insights to plan the following actions. This means the inspection was conducted using a similar principle as storm inspection—Hepta only took photos of faulty cable parts and none of the undamaged cables. This project did not aim to create a fully digitized grid version; the only goal was to document the defects.

Storm inspections can be done when the weather is still bad, but inspecting fibre-optic cable is weather-sensitive and requires special conditions. The weather needs to be dry for a few days to avoid water droplets on the cable posing as false-positive defects. There also needs to be no wind due to the tight manoeuvring spaces. By the second day of the project, the drone pilot was already experienced enough to tell water droplets apart from real defects on the cable.

The first kilometre took one day to inspect, while the rest of the Mustla grid took just two days. In total, it took 19 hours to inspect 6.9 km of the fibre-optic grid. A total of 220 photos of 166 defects were taken. All defects were recorded by photo with the exact coordinates for the maintenance team, and all with just one lineman-drone specialist’s effort!

Future plans involve participating in projects with Connecto to conduct UAV-based inspections for fibre-optic cable damage in the rest of Estonia.

In conclusion, detecting defects on the fibre-optic cable with drones was not done this way, and Hepta found the damages quickly. Innovatively doing something better meant that early adoption of a new approach paid off.