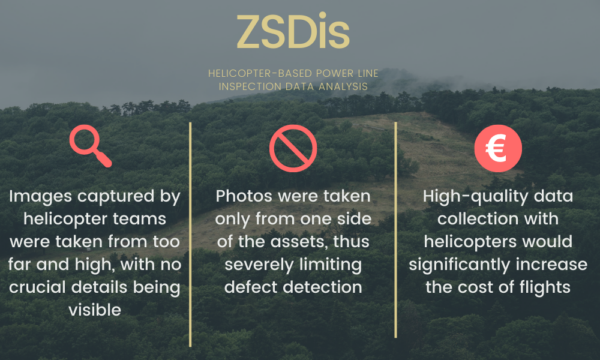

The analysis of the images gathered previously by helicopter inspection teams proved to be challenging, as those images were taken from far and high, with no crucial details being visible. This is a common problem with helicopter-based inspections as they rely on a specialist taking manual notes of defects during the flights and data capture is not thoroughly focused on. Thus, if the specialist in the helicopter does not detect defects during the flight, it is quite difficult to detect them later on from images.

Due to the low-quality data gathered by the helicopter-based inspection teams, Hepta’s grid analysts were only able to conduct basic RGB image analysis. Although the images were of high definition themselves (with sizes of 60MB or 101MP), they were only taken from one side and from a high altitude. Photos taken only from one side of the asset tell only half a story and allow critical defects to be missed easily. And photos taken from a high altitude make it hard to get a clear overview of the severity of defects, especially due to the fact that most of the small details situate there.

A good top-down image used in power line inspections should be good enough to see separate wire strands. To guarantee the detection of the maximum number of defects, it is necessary to photograph from a closer distance and from different (lower) angles. When collecting data from a helicopter, this data quality requirement significantly increases the cost of flights. Using drones shows major qualitative improvements while offering a competitive price at the cost of new technology implementation efforts.