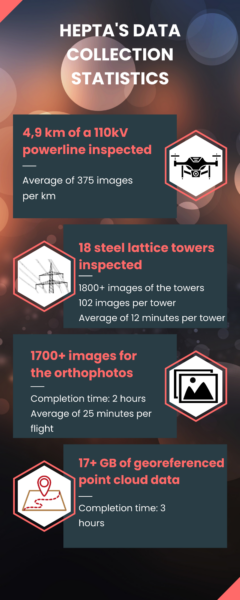

As soon as the data collected during the inspection flights was uploaded to Insights, Hepta’s analysis team started working on it. More than 1800 images of the power line towers, 17oo images for the orthophotos and 17 GB of point cloud data were analysed.

Analysis results for RGB and infrared images

A total of 482 defects were annotated in Hepta Insights, with 40 unique defect types used. The most common defect types were:

- Arcing fittings corrosion

- Corrosion in different nuts and bolts

- Corrosion on the high voltage power line tower

- Suspension clamp corrosion

- Contaminated signs

It took the Hepta analysts on average 48 min to inspect 100+ photos per tower in the Insights platform, with all work being completed in 22 hours.

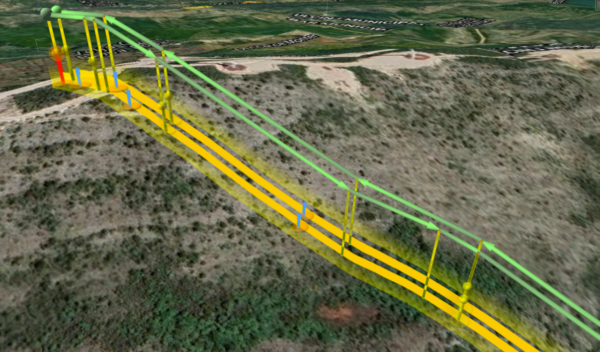

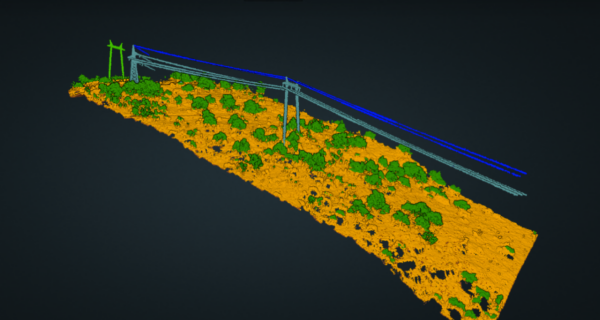

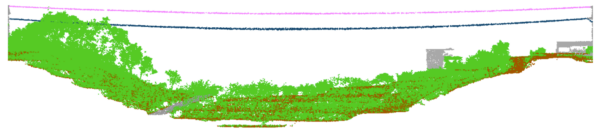

Analysis results for LiDAR point clouds

The data scanned during LiDAR flights was georeferenced and analyzed by Hepta’s inspection team. The point clouds were then classified to separate various segments like towers,

earth and wires. Distance measurements were conducted based on the parameters provided by CGES. In total, the following vegetation defects were found:

- A – level severity defects: 0 (distance to the conductor is less than 1 meter)

- B – level severity defects: 4 (distance to the conductor is less than 3 meters)

- C – level severity defects: 105 (distance to the conductor is less than 5 meters)

Looking at the overall results of the inspections, Hepta’s team was happy to report, that only 3 critical defects were detected during the RGB, infrared and LiDAR inspections. This means that the CGES 110kV power line used for the test project was very well maintained.