Elektrilevi's full scale grid analysis

Background

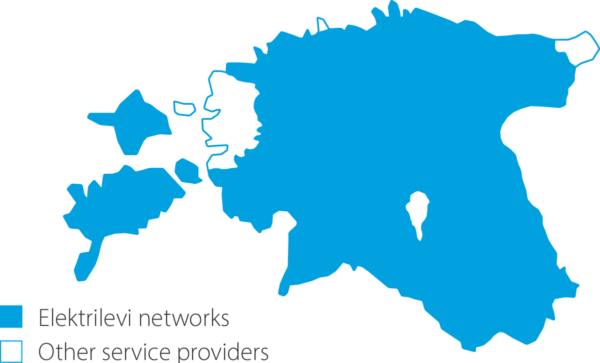

Elektrilevi, the largest distribution network operator in Estonia, covers a staggering 93% of the country’s power line infrastructure. However, it felt derailed and was reluctant to improve its asset management performance.

Despite being a large-scale, publicly owned enterprise, Elektrilevi is well known for its competitive strive towards the future grid and digitization. They strive to offer society and consumers a high-quality experience by effectively developing their network systems and organizational procedures.

Hepta

The success story of Hepta Insights has become known due to a mix of unique skill sets and experience in the team:

- 15+ years of experience in on-ground grid inspection

- 7+ years of experience in helicopter grid inspection

- 8+ years of experience in drone grid inspection

- Including data scientists working with satellite data, software engineers deploying machine learning models, aerospace engineers having previously built manned helicopters

Combining unique skill sets enabled us to approach Elektrilevi’s use case agilely.

“Carrying the weight of analyzing the entire electricity network of Estonia cannot be disrupted with novel solutions promptly and on full-scale from the next day. ”

The heavy responsibility was not to be taken lightly.

Read the full use case below.