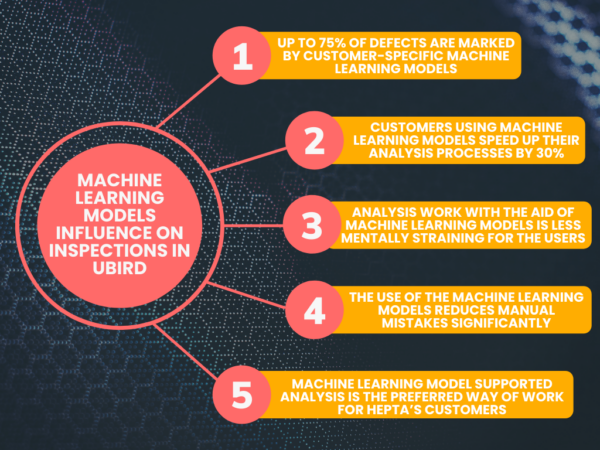

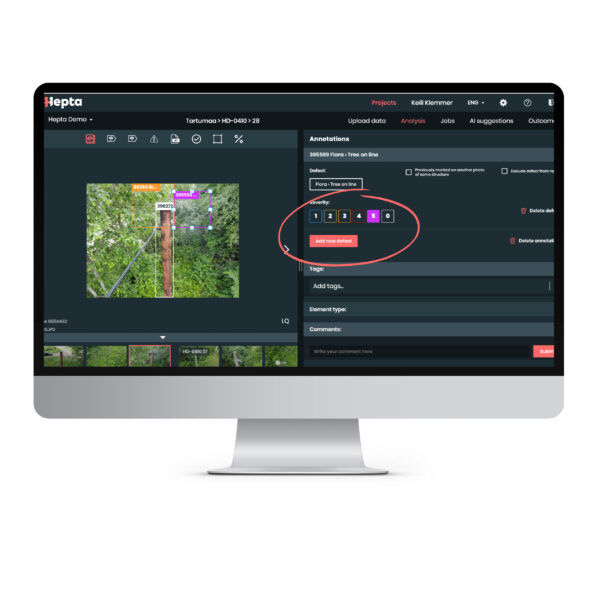

Hepta has developed and continuously improved its machine-learning models in the Insights platform for years. The machine learning models are designed to ease the burden of grid operators’ inspection and analysis efforts. They allow grid operators to:

- analyse thousands of images in a matter of minutes

- improve the quality of inspections

- find more relevant defects

- increase the speed of the analysis process

- and lower the overall cost of inspections

Today, machine learning algorithms are widely used by Hepta’s clients to inspect thousands of power line images from four continents and by a constantly growing number of grid operators.

New AI-models

Due to the success of the machine learning model’s performance in power line inspections, new ones are constantly added to Hepta Insights. The latest additions are focused on detecting crooked cross-arms from power line images.

Cross-arms secure the overhead line wires to the power line pole. The cross-arms get crooked most often due to large branches or trees falling on lines or corrosion effects on their structure. Crooked cross-arms might lead to wires coming into contact with each other or with the surrounding vegetation, thus posing both a blackout and a wildfire threat to the grid operator.

Two new machine-learning models were created to help grid operators detect crooked cross-arms: one for normal, well-maintained cross-arms and one for crooked ones. Both models were extensively trained on a dataset with more than 10,000 images. The result shown in testing for both of the models was exemplary:

- 95.00% precision rate

- F-score higher than 94%

- and 95% recall rate

Yet, these are just the first results of recently created machine learning models. As time passes and the number of analyzed images grows, the models’ performance will improve. We fully expect the new models to become an integral part of the analysis toolset in the future.

If you have questions about the machine learning models or want to apply them to your inspections, don’t hesitate to get in touch with Hepta’s experts!