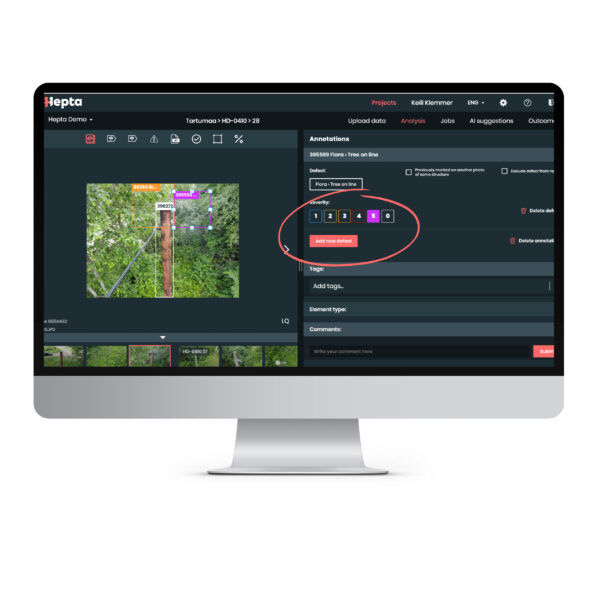

Specialized power line inspection platform for grid operators

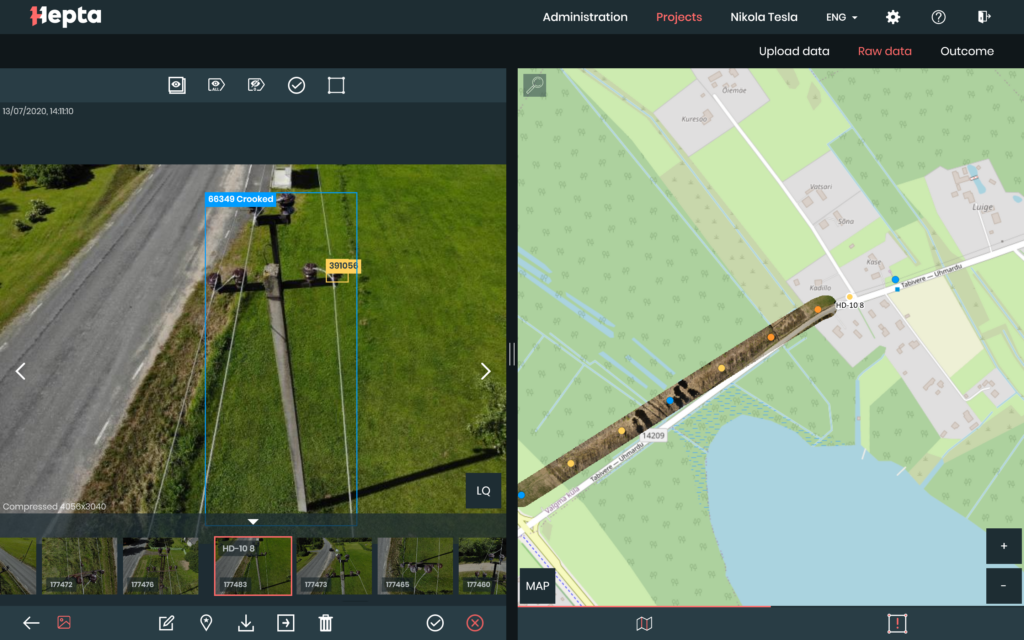

Hepta’s power line inspection platform, Hepta Insights, is designed to ease the burden of grid operators, ensuring a stable power connection to everyone connected to the grid. Instead of relying on the hard manual labour of on-foot patrols or the imprecise and costly work of helicopter-based inspections, Hepta’s clients gather detailed information about their assets with drones. The collected data is then uploaded to Hepta Insights, which allows for comprehensive analysis, GPS-based reporting, and direct work assignments for work teams. The combination of highly detailed data gathering with drones and analysis in a specialized inspection platform allows grid operators to get an in-depth overview of the state of their assets and their most critical parts while also making well-informed decisions based on the reporting.

GPS-based map overview of defects in Hepta Insights

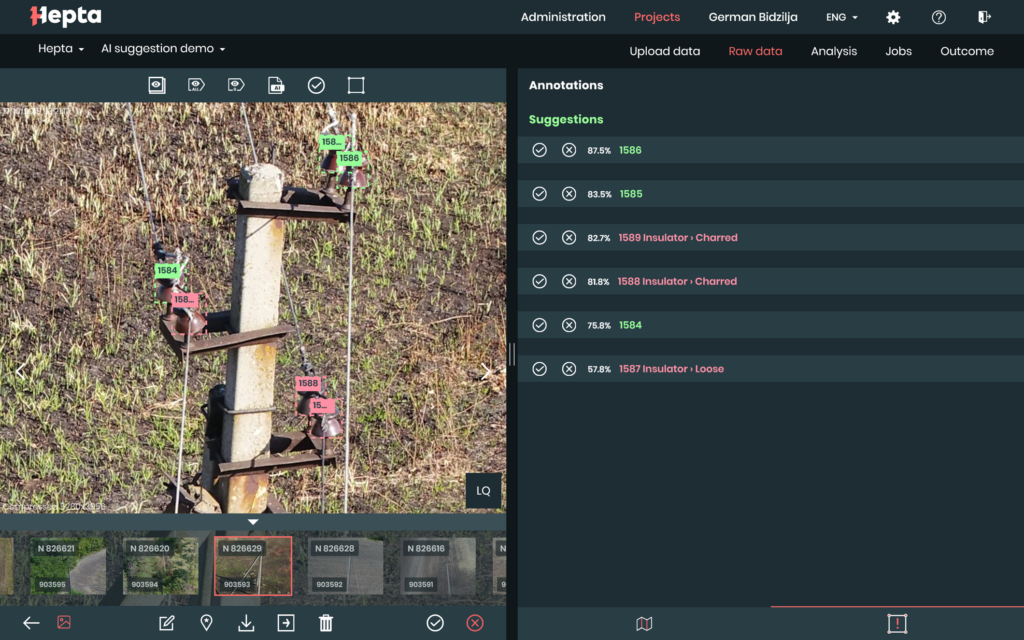

Machine learning in Hepta Insights

One of the crucial parts of Hepta Insights is the machine learning models that help users automatically find defects in the gathered data. They enable users to conduct large-scale data analysis in minutes and detect more defects. Machine learning models are always customer-specific and based on their asset data, thus ensuring high accuracy. Instead of teaching the machine learning models to detect general classification, such as insulators, they are focused on the exact model of insulators used by the customer. This helps to find more relevant defects while also avoiding any misses that could occur with general classification.

Machine learning algorithm annotation suggestions displayed in Hepta Insights

When the machine learning models are run on the customers’ dataset, they mark all images containing defects. The user can then see the images marked with defects and how sure the machine learning models are of the accuracy of those defect types. The machine learning models can analyse thousands of images in minutes, thus offering valuable insights quickly. They also improve the quality of inspections, constantly detecting defects that would have otherwise been missed.

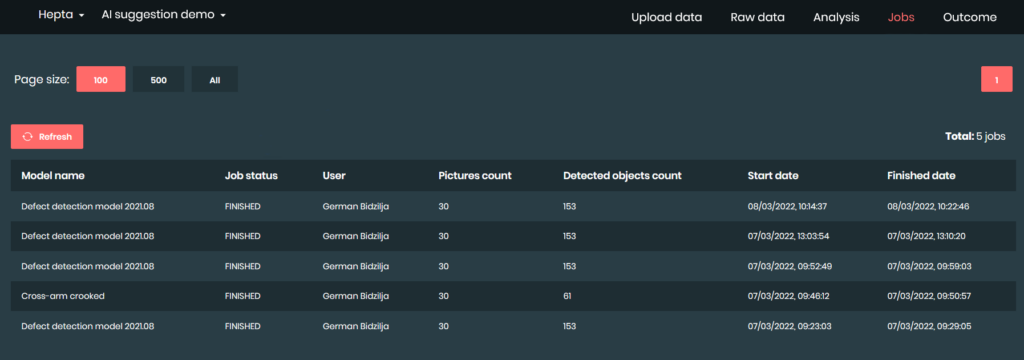

Sample of defects found in overhead power lines by AI models

Machine learning models’ influence on the speed and quality of inspections

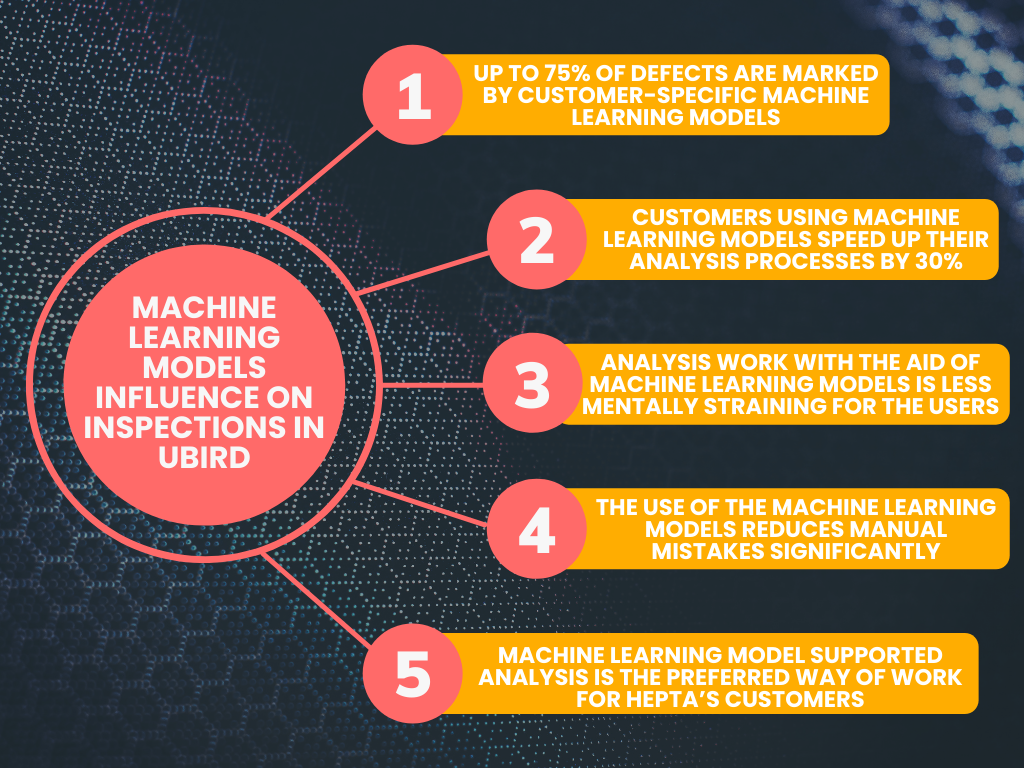

As Hepta’s clients use the machine learning models daily, and their performance is an integral part of the platform, their results are constantly monitored. Since implementing different machine learning models to Hepta Insights, we have seen significant changes in the analysis work conducted on the platform. Machine learning models have detected tens of thousands of defects, helping customers take better care of their grid and avoid outages. Here’s a short overview of the most significant improvements seen in the platform and brought out by clients’ feedback that stem from the use of machine learning models:

- Up to 75% of defects are marked by customer-specific machine learning models

- Customers using machine learning models speed up their analysis processes by 30%

- Analysis work with the aid of machine learning models is less mentally straining for users

- The use of machine learning models reduces manual mistakes significantly

- Machine learning model-supported analysis is the preferred method for Hepta’s customers, and multiple new models are in development