In order to assess the condition of an electricity network, they must be constantly monitored and inspected. Overhead electrical lines often run through hard-to-reach areas, such as dense bushes, swamps, or near water bodies, where inspections are completed by simply walking along the line routes. Considering that Elektrilevi, for example, has more than 60,000 kilometers of network across Estonia, this would take years to complete.

Despite hard, dangerous, and time-consuming work, results are often inaccurate and quickly go out of date. Inaccurate and slowly collected data prompted the Hepta team to look for a solution that would make the process of inspecting electricity networks faster, more precise, and less expensive. Hepta CEO Henri Klemmer discusses how digitization and automation helps, and what solutions they have developed.

Subjective assessment replaced with accurate data

“First, we tried flying piloted helicopters with different cameras and sensors attached. Using helicopters to fly over the power lines was fast and efficient, but expensive,” explained Klemmer. Afterwards, several other solutions were tested and now both satellites and drones are currently being used to collect data. Klemmer recalls that the first set of drones was assembled with the help of Enterprise Estonia’s start-up grant, enabling the company to start offering their service to their first major client.

Earlier, the condition of a power line mast was assessed by eye, but a drone can fly very close to a mast and collect detailed information that the human eye cannot detect. “With the help of a camera and sensor, a digital footprint is created about a mast, which allows the review of all of the relevant detail, whenever needed,” said Klemmer. Remote monitoring drones can fly hundreds of kilometers in one go, detect the observation required and insert the collected information into an automated system. This makes the whole process much more efficient, and faster. “We detect many more errors and defects per line kilometer. We can say that we are 200% more accurate.”

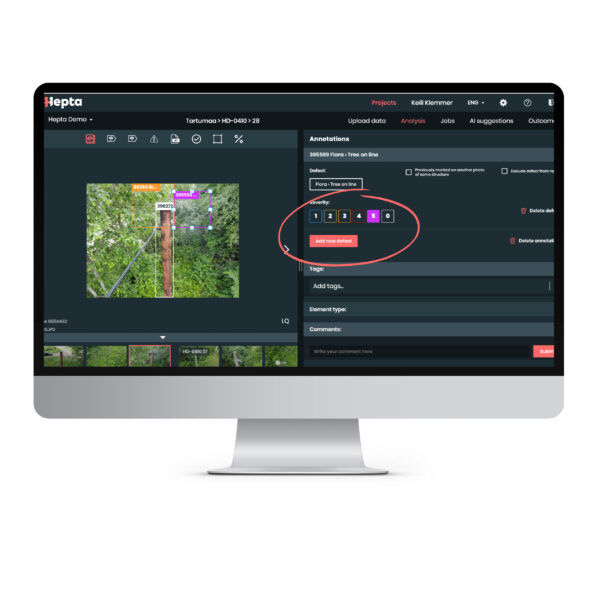

According to Klemmer, the core of Hepta’s added value is digitization, which allows their clients to work faster, safer, detect more errors, and save on network operator costs. Another added value for the client is that instead of an Excel spreadsheet, they can access a three-dimensional up-to-date overview of the electricity networks on their computer at any time.

Incorporating machine learning into human processes

Hepta is also actively involved in the implementation of machine learning. The main focus is on an automated technical analysis platform that processes large amounts of data. “In addition to other sensor data, we also collect images with our drones and apply machine learning to identify the information from the photos. The goal is for the software to increasingly recognize defects,” Klemmer explained, adding that machine learning cannot be a separate goal, but must be integrated with some manual processes. “For example, we upload 10,000 images, which the software then analyzes. The photos that include a defect the software is certain about, do not require human review. The other photos are reviewed by the human eye. But if instead of 10,000 pictures a person looks through 8,000 pictures, that is already a 20% gain.”

Great potential for foreign markets

The corona-crisis has also left its mark on Hepta’s activities. “In the short term the crisis affected us badly, as some of our pilot projects were postponed and the company’s turnover is suffering because of that. Today, we have to make direct sales to clients remotely and that slows down the introduction of new clients,” commented Klemmer. At the same time, Hepta has received feedback from several clients that, in the circumstances of our new reality, digitalized network companies will be able to manage better, and therefore the Hepta project will go on. Thus, Klemmer is convinced that in the long run they will not be negatively affected by the crisis.

Hepta aims to actively sell its software product on a number of markets (Nordic countries, Germany, Portugal, and Ukraine) and to test drone technology in other fields of activity, such as railways and communication lines. Klemmer also praises the export advisors of Enterprise Estonia, who have assisted the company in entering various foreign markets.

“Our bigger vision is to increase the share of automation, so that we can do more tasks automatically. Besides this, we want to develop digital twins of our infrastructure’s environment. If today, we can catch the information with drones, helicopters, and satellites that was here yesterday and are able to assess yesterday’s situation, then we can use (for example) soil and weather data in a simulation, created with a digital twin, to forecast how an electricity network or railway may change over time. Let me give you an example. If the weather forecast calls for strong winds, we can notify Elektrilevi that the probability of trees falling on power lines is 92% in a particular area,” says Klemmer.

This article was originally published on Enterprise Estonia webpage.