Kaamos PV solar panel inspection by using drones

About the client

Established in 2002, the Kaamos Group is an Estonian-owned investment company focused on property development, construction and energy sectors, with assets totalling €270M and over 350 employees.

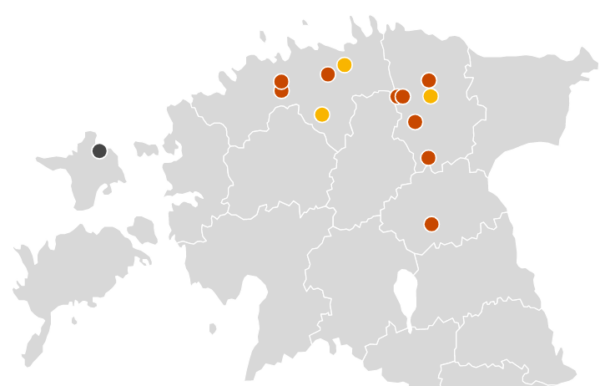

Kaamos Energy, a rapidly growing arm of the group, focuses on sustainable energy, aiming to expand renewable energy production and enhance energy efficiency. Following a successful pilot, Kaamos invited Hepta Insights to inspect 12 additional solar parks (15 MW total) in Estonia in July 2023. The goal was to identify defects in the solar panels to get a full overview of the asset condition and improve efficiency, ensure safety, and maintain their longevity, aligning with Kaamos’ commitment to sustainable energy.

Solar parks included in the scope of the inspection

The importance of conducting solar panel inspections

Solar photovoltaic (PV) panels are composed of multiple interconnected solar cells, typically wired in series to generate the desired voltage. Each solar cell within the panel contributes a specific voltage output, and when these cells are connected in series, their voltages sum up to provide the panel’s overall voltage output. However, once one or more solar cells in a panel are partially or completely shaded, either due to factors like dirt, debris, leaves, overgrown plants, snow, a malfunctioning solar cell, bad wiring, or connectors, the shaded cell becomes a load on the panel rather than a contributor to the electricity generation process. Instead of generating electricity, the shaded cell can act as a resistor, converting some of the incoming sunlight into heat. All of it can lead to a localized increase in temperature within the shaded area, creating what is commonly referred to as a “hotspot.” Due to the characteristics of these flaws, cells that are not functioning properly become excessively heated and deteriorate to the extent that they can harm the entire solar panel.

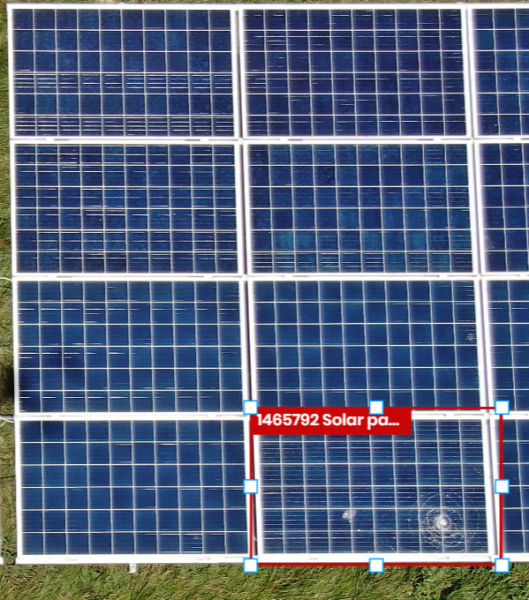

Physical damage to the solar panel |

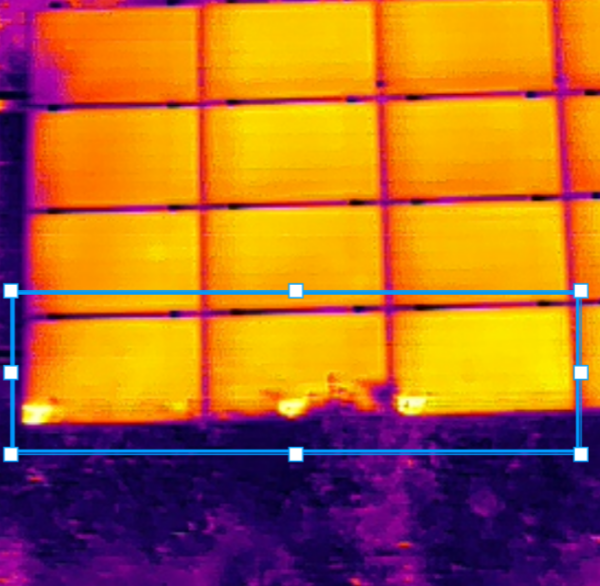

Thermal hotspots caused by untrimmed vegetation |

The hotspot effect is a concern for several reasons

- Reduced efficiency: shaded cells do not contribute to electricity production, reducing the overall efficiency of the solar panel.

- Potential damage: the increased temperature in the shaded area can exceed the cell’s designed operating temperature, potentially causing permanent damage to the cell. It can lead to a reduction in the panel’s lifespan and performance.

- Degradation to the entire panel as the hotspots can heat up adjacent cells, which can also develop hotspots in solar panels.

- Safety hazards: high temperatures in a localized area can pose safety hazards, increasing fire risk or other safety concerns.

Hotspots may remain invisible to the naked eye unless a noticeable color variation, such as a brown blemish, appears on the solar panel. Hence, it is imperative to consistently monitor the performance of solar PV systems to gauge the power output of each module. Identifying most hotspot issues efficiently necessitates specialized measurement techniques. Solar panel thermography stands out as the most effective method for hotspot detection.

Different defect types lead to hotspots

There are many defects that can lead to hotspots on solar panels. There is not much you can do to fix existing hotspots on solar panels, so preventative maintenance is key.

Preventing and mitigating hotspots in solar panels requires addressing various defects through targeted measures. Regular maintenance, proper installation, and the use of advanced technologies can help ensure solar panels operate efficiently and have a long, productive life.

- Mismatched electrical properties: When the electrical properties of solar cells, wiring, and connectors are not well-matched, it causes imbalances that result in localized heating. To prevent this, manufacturers must ensure all components are rigorously tested and quality-controlled.

- Manufacturing defects: Manufacturing defects are such as faulty wiring, damaged solar cells, and loose connections. Defects during production can lead to electrical imbalances and hotspots. Implementing strict quality control during manufacturing, thoroughly testing each panel, and promptly addressing any defects are essential to ensure the panels function correctly and maintain their efficiency.

- Shading: Shading can significantly impact the performance of solar panels by causing a reduction in output and leading to hotspots. Ensuring optimal panel placement to receive maximum sunlight, regularly trimming overgrown vegetation, and using technology such as microinverters or power optimizers can help minimize the effects of shading. Proper planning and maintenance are key to keeping panels efficient and free from hotspots.

- Dirt and debris: Accumulation of dirt and debris on solar panels blocks sunlight, reducing energy production and causing hotspots. Regular cleaning of the panels is essential to maintain their efficiency. Using a soft brush or cloth to gently clean the surface and installing bird deterrents can keep the panels free from obstructions.

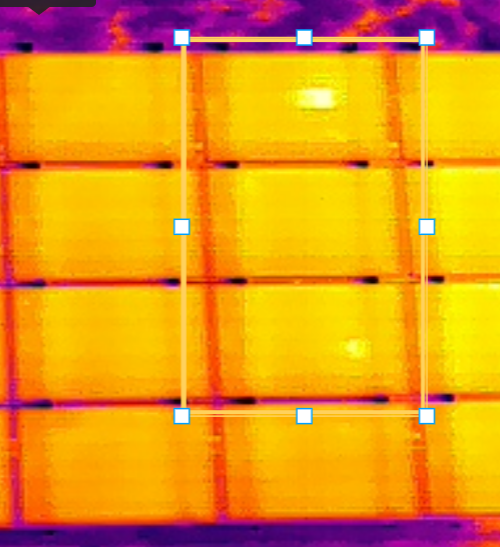

- Bird excrement: Apart from the cleaning aspect, it’s crucial to think about implementing bird deterrents to discourage birds from depositing droppings on the panels. Bird excrement can pose a significant issue since it may contain corrosive substances that have the potential to harm the panel surfaces and diminish their effectiveness. The installation of bird netting or spikes in the vicinity of the solar panels can be an effective means of discouraging birds from perching on or in close proximity to the panels.

Thermal hotspots caused by bird excrement

Inefficient cooling: Inefficient cooling leads to elevated temperatures, reducing panel efficiency and causing hotspots. Ensuring proper airflow around the panels, installing them at optimal angles, and considering active cooling systems such as fans or water-based cooling can help dissipate heat. Proper cooling is essential to maintaining the efficiency and longevity of solar panels.Cracks and damage to solar cells: Cracks and damage to solar cells caused by weather events, impacts, or mishandling, can lead to hotspots. Regular solar panel drone inspections for any signs of damage and prompt repair or replacement of damaged cells are crucial to prevent hotspots and ensure the panels remain efficient and durable.

Using drones to inspect solar panels

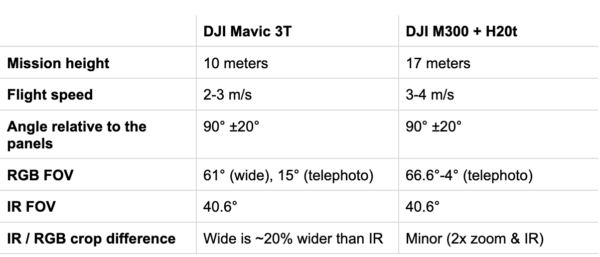

Our drone team used both the DJI Mavic 3T and DJI Matrice 300 RTK drones equipped with a DJI Zenmuse H20T camera.

DJI Mavic 3T

DJI Matrice 300 RTK + DJI Zenmuse H20T

We selected heights that framed entire panels while allowing for minor adjustments. Tests showed the M300 drone could fly faster without blurring. A key advantage of the Matrice series is hot-swapping batteries, reducing downtime and mission interruptions. However, the compact DJI Mavic 3T was ideal for inspecting the 14 smaller parks scattered across the country, as it was easier to handle compared to the larger Matrice drones.

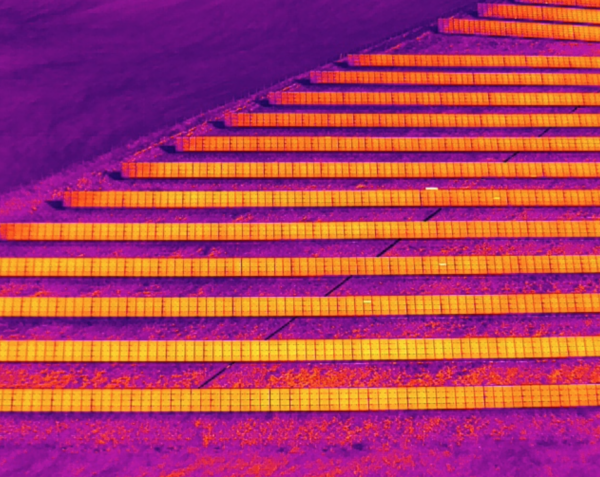

To ensure accurate and reliable data collection during the solar park inspections, specific environmental conditions and flight planning tools were used. Unlike standard practices that recommend automatic mapping missions from higher altitudes for a broader overview, we opted for close-up imagery by flying drones at lower altitudes (10-20 meters) with perpendicular camera angles. While this method required more time (approximately 42 minutes at 2 m/s per mission), it provided superior detail compared to mapping from 40 meters, which takes around 9 minutes.

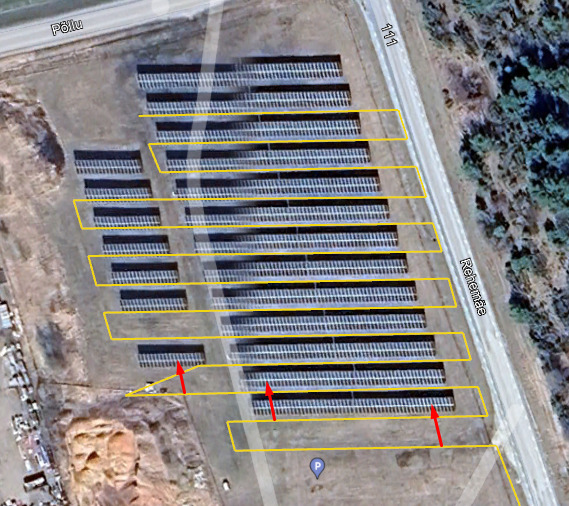

Mission planning was meticulously executed using Google Earth and DJI Terra software. This manual approach allowed us to control every aspect of the flight, including plotting exact trajectories to capture panels at optimal angles. In the DJI Pilot app, interval shooting was set to capture images every 1-2 seconds, with pilots adjusting the camera angles throughout the mission to ensure panels remained in the frame.

Example of a flight mission

Live view from the drone’s remote control

An overview of RGB and IR images was taken to assess the general situation of the park and give better situational awareness. The aim was to capture the whole park while staying below 120 meters (open category limit).

Top-down mapping mission

Low-altitude capture of the panels

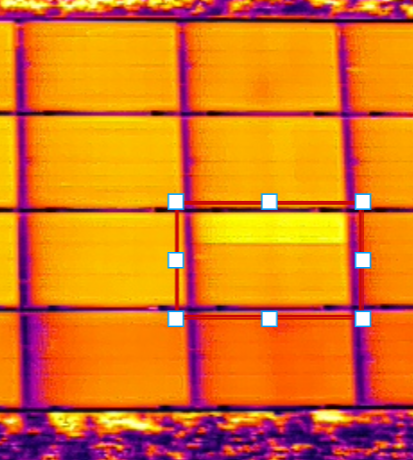

Thermal images of solar panels were captured to identify any underlying hotspots that require attention. A thermographic image provides a visual representation of temperature distribution among objects. In the context of solar panel drone inspection, it boasts a remarkably high accuracy rate in pinpointing hotspots on the panel’s surface.

An example of a thermal defect that drops the panel’s performance

Thermal high-altitude overview of the panels in the park

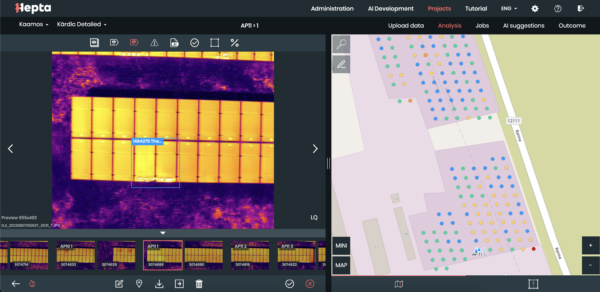

Using AI-enhanced software in the analysis process

Once drone data was captured Hepta Insights software was used to upload all of the data, analyse the visual and thermal defects and count the solar panels. The customer was able to view the findings on the software Outcome view filtering by the type of defect, severity or specific park. Additionally, each of the defects can be viewed based on its location in a specific park or panel and elements are assigned a unique ID number making it easier to export reports and track the maintenance cycle within different tools. Hepta’s machine-learning team continuously trains ML models based on different power lines further enhancing automation and building custom models for counting the panels (element detection).

Hepta Insights software interface for solar panel analysis

Weather and other factors

Sunny, calm weather is crucial for solar park drone inspections. We monitored solar irradiation, pausing missions if it fell below 600W/m² or if wind speeds exceeded 8 m/s. Compared to power line inspections, more downtime was spent waiting for optimal weather, which should be considered when planning deadlines.

During data capture, some parks had mown vegetation while others did not. Vegetation can cause hotspots on panels, visible in thermal images. It’s uncertain if these hotspots would disappear after mowing, so Kaamos concluded that grass should be mown before thermographic inspections.

Parks hosting herds of sheep were highly efficient at keeping the vegetation at bay and tidy.

Sheep eating grass during solar park inspections

Conclusion

“Working with Hepta Insights on the solar parks was a productive and valuable experience. Hepta’s quick response within our tight timeframe provided invaluable insights. Their thermal imaging analysis helped identify and address issues in panels. The inspection of Kärdla solar park revealed the poor condition of the panels, leading to the ongoing replacement of 400 panels. This proactive approach has highlighted the importance of using advanced technology like thermal camera-equipped drones for ongoing maintenance. Once drone data was captured, Hepta’s AI-enhanced software analyzed the visual and thermal defects, and counted the solar panels. The findings, viewable by defect type and severity, allowed for efficient maintenance planning. The thorough and well-organized report from Hepta was crucial. We recommend Hepta for their expertise and comprehensive service.” Hardi Puusepp, Production Manager of Kaamos.

The comprehensive drone inspection of Kaamos Energy’s solar parks, conducted by Hepta Insights, successfully identified and addressed critical issues affecting the performance and safety of their PV panels. By employing drone technology and meticulous planning, we ensured high-quality data capture, revealing defects such as hotspots, shading, and physical damage that could compromise energy efficiency and longevity.

Our approach involved flying drones at lower altitudes with perpendicular camera angles, which allowed for detailed thermographic and RGB imagery. This ensured precise defect detection and facilitated the counting of solar panels using RGB image data. This element identification process helped the solar park owner accurately verify the number of panels and identify any physical damages.

The use of both DJI Mavic 3T and DJI Matrice 300 RTK drones provided flexibility and efficiency in various conditions, demonstrating the advantages of each in different aspects of the mission.

The importance of optimal weather conditions and regular maintenance was underscored throughout the project, highlighting the need for consistent monitoring to prevent and mitigate potential issues. Our findings also emphasized the value of proper vegetation management around solar panels to avoid shading-related hotspots.

“Diving into the solar energy sector is an exciting new vertical for us. While we have a robust history with electricity networks, it’s invigorating to see our AI tools and technology working seamlessly at scale for photovoltaics. Harnessing renewable energy is undeniably the future, and ensuring that solar installations run efficiently is a pivotal part of that journey. Our partnership with Kaamos Energy underlines our commitment to this future, and showcases the importance of regular inspections and timely interventions.” Henri Klemmer, CEO of Hepta Insights

The project outcome was a detailed solar panel inspection report with a list of identified defects visible on the Hepta Insights asset analysis platform. This software played a crucial role in organizing and presenting the data, enabling Kaamos Energy to efficiently address and rectify the issues identified.

This project exemplifies the synergy between using innovative technology and strategic planning in maintaining and improving solar energy systems. The insights gained from the inspections will aid Kaamos Energy in optimizing its solar park operations, ensuring long-term sustainability and efficiency in its renewable energy initiatives.

Regular, high-quality inspections using drones not only enhance the performance and lifespan of solar panels but also align with Kaamos Energy’s commitment to environmentally friendly energy solutions. The success of this project sets a precedent for future inspections and highlights the critical role of innovative approaches and advanced software in advancing the renewable energy sector.