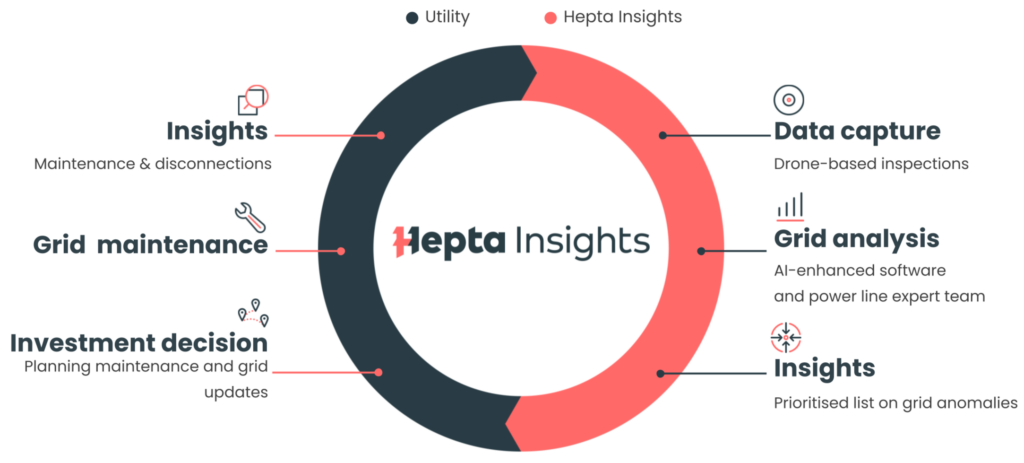

Our mission is to make power grids more resilient with AI-enhanced analysis

-

Our approach maximizes the amount of anomalies found. We use AI to maximize the efficiency of operations.

-

Finding the most anomalies leads to the lowest total maintenance cost over the long term.

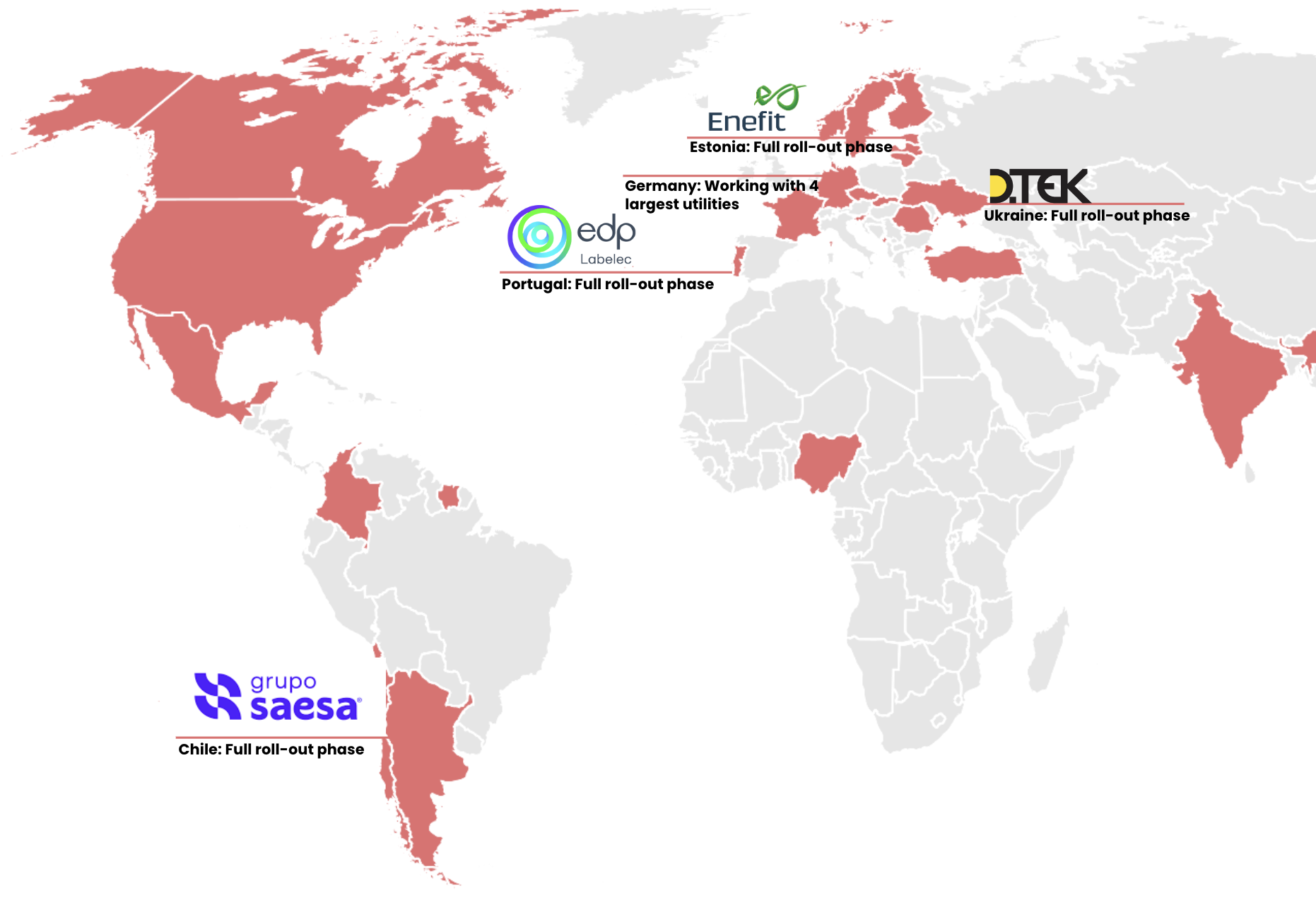

Worldwide impact

Hepta is giving its clients the tools to succeed, no matter the location or size of the task.

Locations

- Hepta’s solutions have been successfully implemented by more than 30 DSOs and TSOs in 21 countries.

- Our software addresses the real-life needs of inspection teams and is today used to inspect more than 3000 KM of power lines every month.

Measurable results

- SAIDI score improved 300% (DTEK Grids)

- Inspection cycle decreased from 7 years to 2,5 years (Enefit Connect)

- Average costs saved for utilities 3 000 000 euros per year

References

FAQ

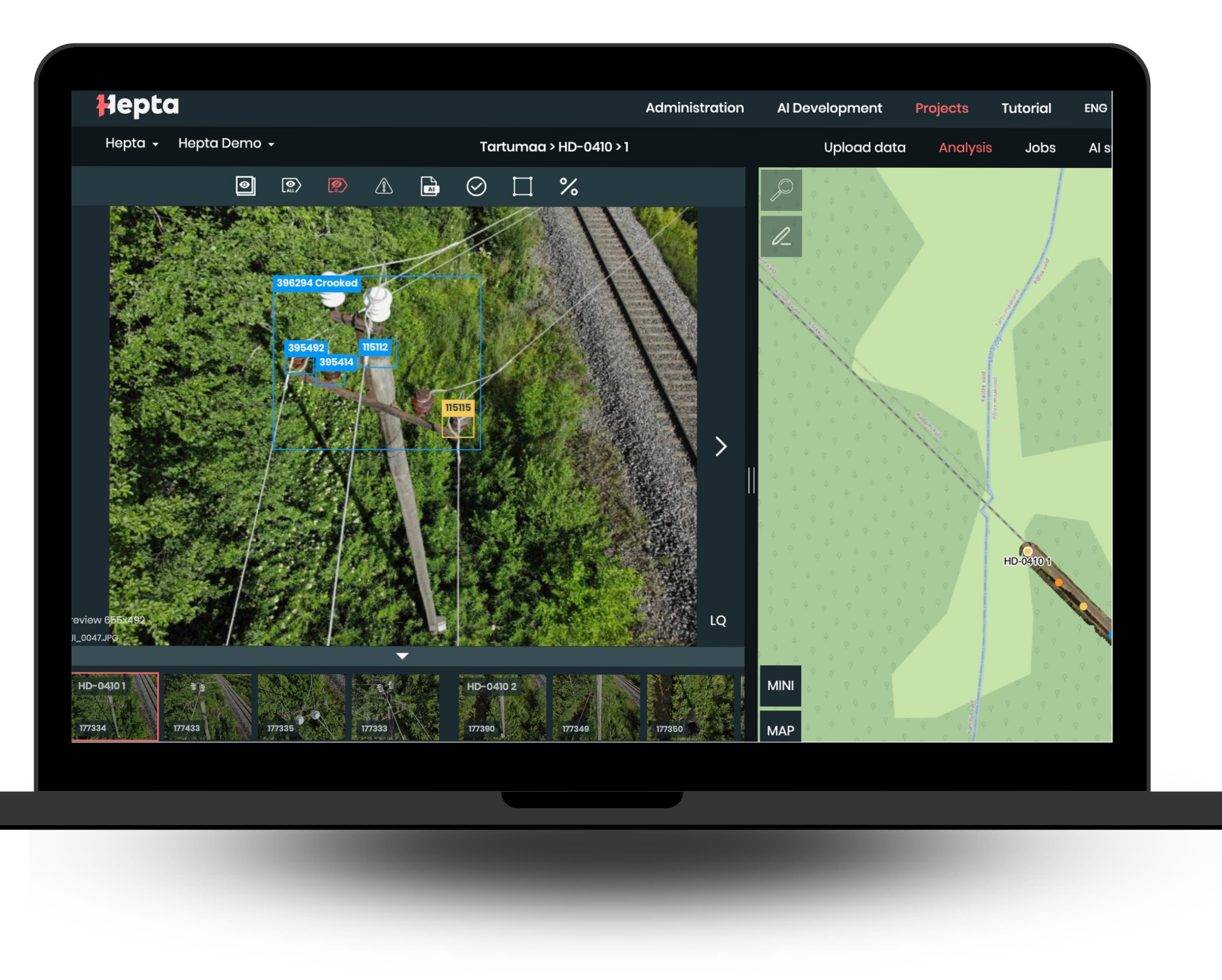

We detect a wide range of issues across transmission and distribution grids, including mechanical faults, corrosion, missing components, thermal anomalies, vegetation encroachment, and more.

We support diverse data sources such as drone imagery, helicopter footage, LiDAR pointclouds, satellite data, and ground patrol photos.

We leverage an AI-enhanced approach to train and run machine learning models that automatically detect anomalies and assign severity risk scores, streamlining the analysis process. Analysis findings are then reviewed and validated by experienced grid experts to ensure accuracy and eliminate false positives.

Yes. We offer API and custom integration options for CMMS (Computerized Maintenance Management Systems), EAM (Enterprise Asset Management), and GIS (Geographic Information Systems).

Absolutely. We comply with industry best practices for data security, with options for cloud or on-premise deployment to meet your compliance needs.

You can start seeing insights within days. We offer fast onboarding, pre-trained models, and full deployment support to get your team up and running quickly.

Not at all. Insights platform is built for operational teams with no technical background required. The platform is intuitive and easy to use. Our team also provides end-to-end ML training and expert analysis support to guide you through every step.

Yes. You can use Hepta’s pre-trained models or request custom model training tailored to your asset types and inspection data.

Hepta combines deep domain expertise in power grids with advanced AI-enhanced anomaly detection and fully integrated inspection workflows—purpose-built for power grid operators.